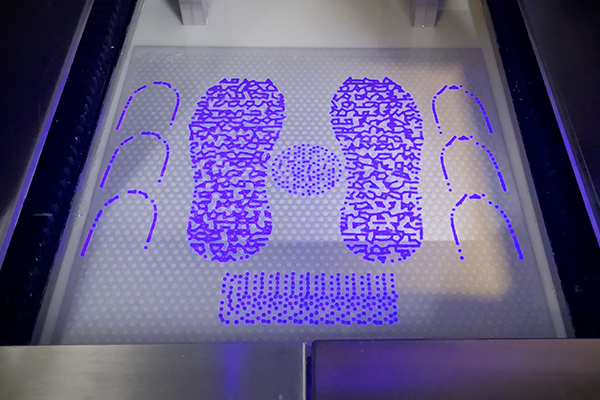

Made Plus uses the ETEC Xtreme 8K to change the way footwear is made through an on-demand manufacturing model enabled by technologies like 3D printing. The speed of the Xtreme 8K enables production of Elastic ToughRubber with the durability and flexibility for end use.

Learn how DLP printing on the Xtreme 8K enables Made Plus to unlock new innovations, customization, and on-demand production with low-inventory so they can produce footwear domestically.

In this case study you will learn:

For more information on how we protect your privacy, please review our Privacy Policy.

© 2026 ENVISIONTEC US LLC. All rights reserved.