Learn how industry-leading material performance can help lead to applications that rival traditional production methods while offering manufacturing flexibility for business growth.

Register to watch the on-demand webinar.

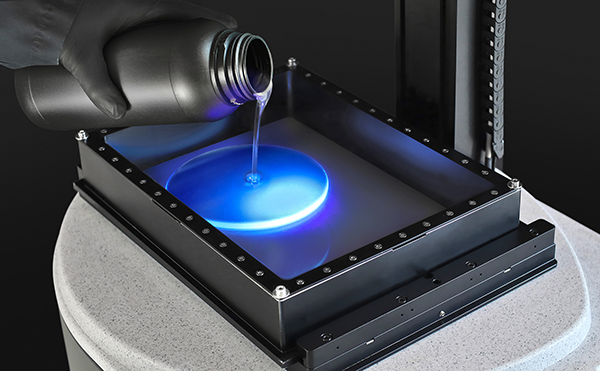

Differentiated photopolymers are a key part of propelling 3D printing into a new era of production. Resins with targeted property sets tailored to serve the material requirements of end-use products can be formed into lightweight, complex, and variable shapes with ease using top-down digital light processing (DLP) technology. And with materials that make parts less dense without a strength drop-off, optimization for de-densification adds further value through lightweighting.

Stress-Strain curve evaluations traditionally factor out the design to evaluate how a material will perform. However, in the world of additive manufacturing, 3D architectures change the game. Designers can now look at materials in a more toughness-per-density way to optimize the strength-to-weight ratio (proportional to performance-to-cost ratio) of their component.

For more information on how we protect your privacy, please review our Privacy Policy.

© 2026 ENVISIONTEC US LLC. All rights reserved.